TIG welding collision systems revolutionize auto body repair with their advanced technology, offering unparalleled accuracy and efficiency in frame repair and bumper restoration. These systems, powered by laser sensors and cameras, detect real-time obstacles, minimizing human error and maximizing structural integrity. By automatically adjusting parameters to avoid contact with debris or paint services, they enhance repair quality and speed while ensuring the safety of both equipment and personnel. Transforming automotive workshops, these systems prioritize efficiency and safety, enabling precise control of welding parameters to minimize heat input and damage to adjacent components, resulting in faster turnaround times, higher-quality work, and a safer workspace.

In the dynamic landscape of modern manufacturing, TIG welding collision systems stand as pivotal game-changers, enhancing safety and efficiency. This article delves into the intricate world of these advanced systems, offering a comprehensive overview for professionals and enthusiasts alike. From understanding the basics of TIG welding collision technology to exploring cutting-edge detection methods and their diverse applications, we unravel the secrets behind this revolutionary approach to weld safety.

- Understanding TIG Welding Collision Systems: A Basic Overview

- The Technology Behind Modern Collision Detection and Avoidance

- Advantages and Applications of Advanced TIG Welding Safety Features

Understanding TIG Welding Collision Systems: A Basic Overview

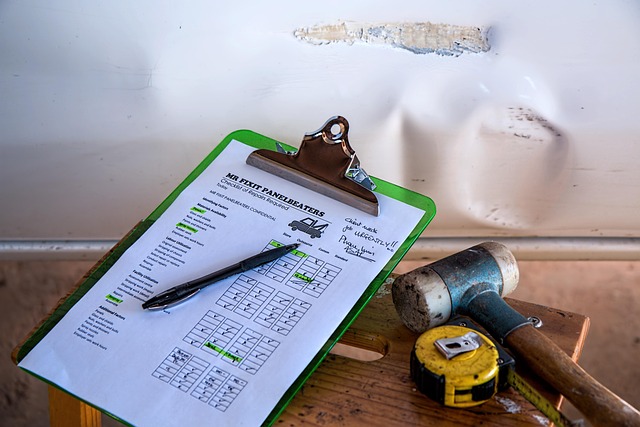

TIG welding collision systems are designed to automate and streamline the process of repairing vehicle bodywork, particularly in auto frame repair and bumper repair scenarios. These advanced systems use a combination of robotic arms and precise laser sensors to detect and measure damage in real-time. By integrating cutting-edge technology, TIG welding collision systems offer unparalleled accuracy and efficiency, ensuring that every repair is not just visually appealing but also structurally sound.

The heart of these systems lies in their ability to analyze and adapt to complex shapes and contours commonly found in modern vehicles. Whether it’s repairing a dented fender or realigning a misaligned panel, the TIG welding collision system guides the welder with laser-guided precision, minimizing human error and maximizing repair quality. This not only enhances the speed of auto frame repair but also contributes to the overall longevity of the vehicle’s structural integrity.

The Technology Behind Modern Collision Detection and Avoidance

Modern TIG welding collision systems leverage advanced technologies to ensure precise and safe welding processes. At the heart of these systems are sophisticated sensors and cameras that continuously monitor the workspace, detecting any obstacles or potential collisions in real-time. This technology is particularly crucial for complex welds involving tight spaces or intricate designs, where human eyes might miss critical details.

By integrating these collision detection mechanisms, TIG welding machines can automatically adjust their parameters to avoid contact with foreign objects, including car paint services, bumper repair components, and other debris. This not only enhances the quality of vehicle collision repair but also prevents costly damage to both the welding equipment and the workpiece, ensuring efficient and effective welding operations across various industries.

Advantages and Applications of Advanced TIG Welding Safety Features

Modern TIG welding collision systems offer a multitude of advantages that significantly enhance safety and efficiency in automotive workshops, particularly in auto body shops and those providing auto repair services. These advanced features are designed to prevent accidents, protect workers, and ensure the structural integrity of vehicles undergoing frame repair.

One notable application is real-time collision detection. Sensors integrated into the welding system can identify potential obstacles, such as metal shavings or nearby personnel, and automatically trigger safety protocols. This prevents incidents that could lead to severe injuries in a bustling auto shop environment. Moreover, these systems enable precise control of welding parameters, minimizing heat input to surrounding areas, which is crucial for successful auto frame repair without damaging adjacent components. The combination of collision avoidance and controlled welding ensures faster turnaround times, higher-quality work, and a safer workspace.

Modern TIG welding collision systems, powered by advanced technology, significantly enhance workplace safety and efficiency. By leveraging sophisticated sensors, machine learning algorithms, and real-time data analysis, these systems can detect and avoid obstacles with remarkable accuracy. The advantages are vast, from reducing accidents to minimizing downtime, making them indispensable for industries relying on precise and secure welding processes. TIG welding collision systems continue to evolve, promising an even safer and more streamlined future for welders worldwide.