TIG welding collision systems enhance precision and efficiency in panel fabrication, ideal for auto body repairs and vehicle paint restoration. By detecting and minimizing arc-surrounding material collisions, these tools preserve delicate surfaces, reduce waste, speed up turnaround times, and ensure high-quality workmanship, making them indispensable for complex panel configurations, auto glass repair, fleet services, hail damage restoration, and classic car restoration.

In the realm of panel fabrication, precision and efficiency are paramount. This is where TIG (Tungsten Inert Gas) welding collision systems emerge as game-changers. Understanding these advanced systems involves grasping their unique ability to automate and optimize welds, reducing human error and enhancing quality. This article delves into the benefits of integrating TIG welding collision systems, explores when to implement them, and provides insights for professionals in panel fabrication looking to enhance their processes.

- Understanding TIG Welding Collision Systems

- Benefits for Panel Fabrication Processes

- When to Implement These Systems in Practice

Understanding TIG Welding Collision Systems

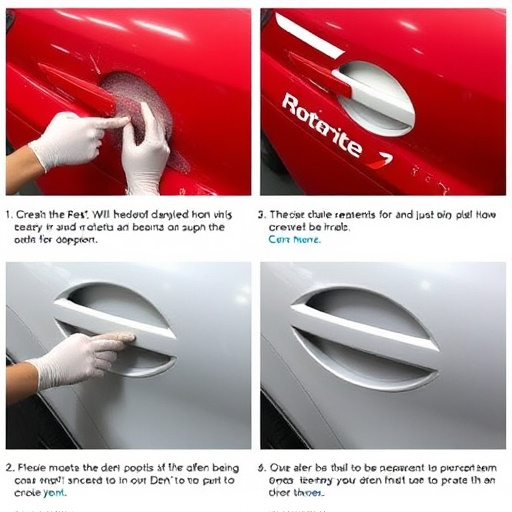

TIG welding collision systems are specialized tools designed to enhance precision and efficiency during panel fabrication, particularly in auto body repairs and vehicle paint restoration. These systems utilize a unique approach by detecting and minimizing collisions between the welding arc and surrounding materials, which is crucial when dealing with delicate surfaces. By employing advanced sensors and control mechanisms, they enable precise control over the welding process, ensuring accurate results without damaging adjacent components.

This technology is particularly valuable in scratch repair and vehicle paint repair processes, where maintaining the integrity of the existing finish is essential. It allows welders to focus on the desired joint while keeping nearby surfaces safe, streamlining the overall fabrication process. Moreover, TIG welding collision systems contribute to faster turnaround times, higher quality workmanship, and reduced wastage, making them a game-changer in modern auto body repairs.

Benefits for Panel Fabrication Processes

In panel fabrication, TIG welding collision systems offer significant advantages that streamline production processes and enhance quality control. These advanced systems integrate real-time feedback mechanisms, ensuring precise alignment and minimal overlap during welds. This precision is particularly beneficial for complex panel configurations, where maintaining structural integrity and aesthetic appeal is paramount. By reducing the occurrence of misalignments and excessive welding, TIG welding collision systems not only accelerate production times but also minimize material waste, thereby lowering manufacturing costs.

Moreover, incorporating TIG welding collision systems can be a game-changer for industries dealing with auto glass repair, fleet repair services, or hail damage repair. The ability to precisely weld with minimal impact on surrounding materials is crucial for restoring vehicles to their pre-damage condition, preserving the original integrity and value of the panel. These systems’ versatility and accuracy make them indispensable tools in ensuring high-quality repairs, satisfying both customers and insurance providers alike.

When to Implement These Systems in Practice

In the realm of panel fabrication, especially for tasks involving intricate metalwork like automotive restoration and classic car restoration, TIG welding collision systems offer significant advantages. These systems are implemented when precision and minimal waste are paramount. For instance, in car bodywork services, where every detail matters, TIG (Tungsten Inert Gas) welding collision systems ensure clean, accurate cuts, reducing the risk of errors that can lead to costly rework.

The decision to adopt these systems is driven by the complexity of the project and the need for high-quality outcomes. Classic car restoration projects, known for their meticulous nature, benefit greatly from TIG welding collision systems’ ability to maintain historical integrity while achieving modern fabrication standards. This technology is particularly valuable when dealing with delicate metal components, ensuring a seamless blend of old and new in these cherished vehicles.

TIG welding collision systems are a game-changer for panel fabrication, offering enhanced precision and efficiency. By understanding these systems and their benefits, fabricators can navigate complex projects with ease. The optimal time to implement these technologies is during intricate designs or when faster production times are required, ensuring a seamless and successful welding process.