TIG welding collision systems transform automotive restoration by offering precise, efficient paintless dent repair, preserving vehicle aesthetics with swift, accurate techniques for subtle dents and scratches. These advanced systems revolutionize metalwork in collision repair and customization, minimizing error margins for stronger welds on complex tasks like frame straightening. In manufacturing and custom metal fabrication, TIG welding systems provide clean, accurate welds for intricate designs and structural integrity, automating processes to reduce labor costs and improve productivity.

In today’s precision-driven manufacturing landscape, the efficiency and accuracy of welding processes are paramount. The introduction of TIG (Tungsten Inert Gas) welding collision systems has revolutionized industrial practices by offering unprecedented control and precision. This article explores how these advanced systems unlock unparalleled efficiency, enhance precision in navigation, and maximize TIG advantages across various industrial applications, ensuring superior weld quality and reduced waste.

- Unlocking Efficiency: TIG Collision Systems' Role

- Enhancing Precision: Navigating Welding Challenges

- Industrial Applications: Maximizing TIG Advantages

Unlocking Efficiency: TIG Collision Systems' Role

In the realm of automotive restoration and repair, achieving precision and efficiency is paramount. This is where TIG welding collision systems emerge as a game-changer, particularly in the context of paintless dent repair. These advanced systems revolutionize the way body shop services are delivered, especially when dealing with delicate metalwork. By combining precise welding techniques with collision repair methodologies, technicians can now address fender benders and minor dents with unmatched accuracy.

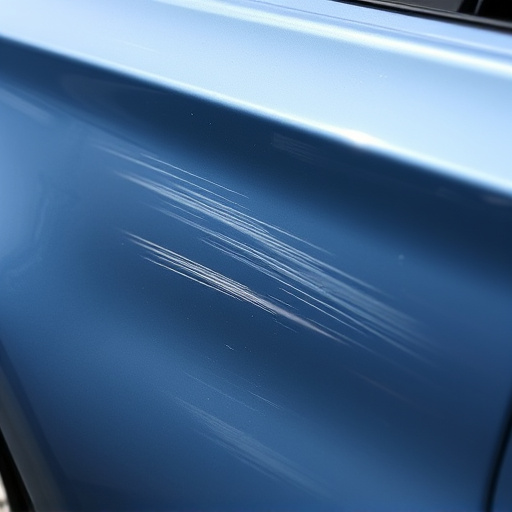

The integration of TIG (Titanium Gas) welding into collision systems offers numerous benefits. It enables faster repair times without compromising the integrity of the vehicle’s original body panels. This is particularly advantageous in minimizing the impact on a car’s overall aesthetics, ensuring that even the most subtle of dents and scratches are removed, leaving no trace of their existence. Thus, TIG welding collision systems not only enhance efficiency but also contribute to higher-quality, more satisfying repair outcomes for both body shop professionals and vehicle owners alike.

Enhancing Precision: Navigating Welding Challenges

In the realm of automotive repair and customization, precision is key, especially when dealing with intricate metalwork. TIG welding collision systems have emerged as a game-changer in this sector, offering unparalleled accuracy and control during the welding process. These systems are designed to navigate complex challenges that often arise from vehicle bodywork repairs, such as frame straightening or even minor fender benders.

By employing advanced technology, TIG (Titanium Gas) welding collision systems ensure minimal error margins, making them ideal for intricate joins and structural repairs. The precision afforded by these systems not only results in stronger welds but also allows for more complex designs to be realized, enhancing the overall aesthetic appeal of vehicle customization projects. This level of control is particularly valuable when dealing with curved surfaces or tight spaces commonly found in modern vehicle designs.

Industrial Applications: Maximizing TIG Advantages

In industrial applications, TIG welding collision systems offer a significant advantage by combining precision with efficiency. These advanced systems are particularly valuable in sectors such as automotive manufacturing and custom metal fabrication. By leveraging TIG (Gas Metal Arc Welding) techniques, which involve a non-consumable tungsten electrode, the process allows for highly accurate and clean welds. This precision is crucial for intricate designs and structural integrity, making it ideal for auto repair shops and specialized car dent repairs that demand high-quality results.

The collision systems further enhance these benefits by automating and optimizing the welding process. In an auto repair near me setting, for instance, these systems can streamline the repair of complex panels and components, ensuring consistent quality across multiple vehicles. This precision advantage not only reduces labor costs but also improves overall productivity, making it a game-changer in modern manufacturing and auto repair industries.

TIG welding collision systems have emerged as game-changers in industrial manufacturing, offering unprecedented precision and efficiency. By seamlessly integrating advanced navigation technologies, these systems tackle complex welding challenges, ensuring consistent and high-quality results. As we’ve explored through this article, the advantages of TIG welding are now more accessible than ever, revolutionizing various industries and setting new standards for excellence.