TIG welding collision systems revolutionize car bodywork repair by offering precise, corrosion-resistant welds. This technique minimizes heat damage, prevents rust, and ensures structural integrity in complex auto body repairs, making it ideal for modern vehicle maintenance.

In the realm of metal fabrication, understanding corrosion is paramount for ensuring structural integrity. Corrosion not only weakens materials but also accelerates wear and tear, leading to costly repairs and safety hazards. This article explores how TIG welding collision systems emerge as a game-changer in enhancing corrosion resistance. We delve into the science behind corrosion, dissecting its impact on metals. Subsequently, we provide an in-depth analysis of TIG welding techniques and elucidate how collision systems fortify these joints against corrosive elements.

- Understanding Corrosion and Its Impact on Metals

- TIG Welding: A Deep Dive into the Technique

- Collision Systems: Enhancing TIG Welding's Corrosion Resistance

Understanding Corrosion and Its Impact on Metals

Corrosion is a natural process that occurs when metals interact with their environment, leading to degradation and potential structural failure over time. This phenomenon can be accelerated by various factors such as moisture, salt, acids, and other chemicals present in the air or specific environments. In the context of vehicles, corrosion can significantly impact the integrity of metal components, affecting both aesthetics and safety. Rust, for instance, not only weakens the structural integrity of a car’s body but also contributes to its overall deterioration, leading to costly repairs.

TIG (Tungsten Inert Gas) welding collision systems have emerged as powerful tools in enhancing corrosion resistance in car repair shops and vehicle collision repair processes. By utilizing advanced TIG welding techniques, these systems enable precise metal fusion, creating strong bonds that are less susceptible to corrosion. Unlike traditional welding methods, TIG welding minimizes heat input, preserving the metal’s natural properties and promoting better structural integrity post-repair. This is particularly beneficial in car paint repair scenarios, where maintaining a seamless finish that resists rust formation is crucial for long-term vehicle performance and aesthetic appeal.

TIG Welding: A Deep Dive into the Technique

TIG welding, or Tungsten Inert Gas welding, is a precise and powerful technique used in automotive industries and beyond for its exceptional fusion capabilities. This method involves the use of a non-consumable tungsten electrode, which generates an arc when struck against the workpiece, creating a hot zone that melts and fuses the metal. By controlling the intensity of the arc and the flow of gas, welders can achieve precise, clean, and strong bonds, making TIG welding ideal for intricate and detailed work.

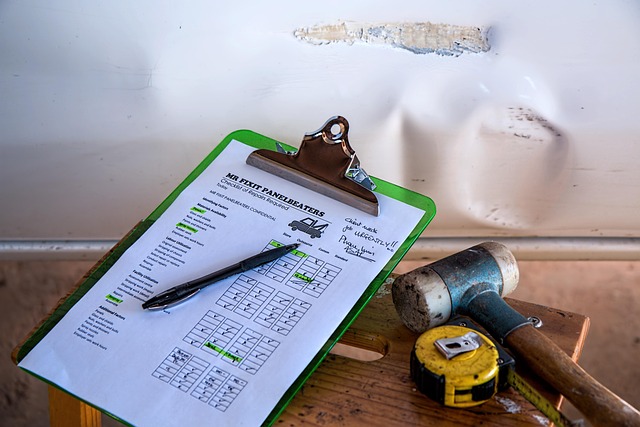

In the context of car bodywork services and collision repair shops, TIG welding collision systems offer significant advantages. These systems are designed to handle complex auto body repairs, ensuring that each joint is seamlessly fused, leading to increased corrosion resistance. The precision afforded by TIG welding allows for minimal heat input, reducing the risk of metal fatigue or damage to surrounding areas, a common issue in car collision repair. This meticulous approach not only guarantees structural integrity but also longevity, as the strong bonds created by TIG welding can withstand harsh environmental conditions, providing superior protection against rust and corrosion.

Collision Systems: Enhancing TIG Welding's Corrosion Resistance

TIG welding collision systems are revolutionizing the way we approach vehicle restoration and auto body repairs. These advanced systems play a pivotal role in enhancing corrosion resistance, ensuring that vehicles undergoing repair or construction maintain their structural integrity for longer periods. By combining precise TIG welding techniques with specialized collision systems, auto repair services can achieve robust and durable welds, even in complex areas of the vehicle body.

The integration of these systems offers significant advantages over traditional methods, particularly in terms of corrosion protection. Collision systems, designed to manage the heat input during welding, minimize heat-affected zones, a common issue in metalworking. This precision reduces the risk of galvanic corrosion by maintaining the original material properties, especially crucial for components exposed to harsh environmental conditions. Thus, TIG welding collision systems not only speed up vehicle body repair but also guarantee superior corrosion resistance, making them indispensable in modern auto repair services.

TIG welding collision systems represent a significant advancement in corrosion resistance, offering a robust solution for metal fabrication. By combining precise welding techniques with specialized collision systems, these innovations mitigate corrosion’s detrimental effects on structural integrity. This enhanced durability makes them ideal for demanding applications, ensuring longer-lasting and more reliable results in various industries. Embracing TIG welding collision systems can thus drive innovation, foster efficiency, and promote the creation of superior, corrosion-resistant metal products.