TIG welding collision systems transform auto detailing and repair by offering unparalleled precision and weld quality. Utilizing advanced technology, these systems minimize heat input beyond target areas, resulting in cleaner, stronger welds with less post-weld cleaning. This enhances structural integrity, particularly for intricate metalwork, while improving aesthetic finishes that can withstand modern transportation demands. In collision repair centers, TIG welding collision systems speed up repairs, reduce rework, and boost customer satisfaction, also excelling in delicate scratch repairs without damaging paint or finish.

TIG welding collision systems are transforming industrial welding processes, delivering cleaner and stronger welds with minimal defects. This advanced technology integrates real-time collision detection and precise control, allowing welders to optimize parameters for superior results. By understanding the fundamentals of these systems and their advantages, industries can leverage their capabilities to enhance quality, efficiency, and productivity in various applications. Explore how TIG welding collision systems are revolutionizing welding practices across diverse sectors.

- Understanding TIG Welding Collision Systems: The Basics

- Advantages of Using TIG Welding Collision Systems for Cleaner and Stronger Welds

- Application Examples: Where TIG Welding Collision Systems Shine

Understanding TIG Welding Collision Systems: The Basics

TIG welding collision systems are designed to enhance the precision and quality of TIG (Tungsten Inert Gas) welding processes in auto detailing and repair settings, particularly within collision repair centers. These systems leverage advanced technology to ensure cleaner welds with improved structural integrity. By focusing on the collision between the welding arc and the metal surface, these systems minimize heat input beyond the desired area, preventing excess melting and burn-through.

This precision is achieved through a combination of controlled gas flow, precise arc manipulation, and real-time feedback mechanisms. Auto repair shops benefit from reduced post-weld cleaning and finishing due to the system’s ability to create stronger, more aesthetically pleasing welds. For collision repair centers dealing with intricate metalwork, TIG welding collision systems offer a game-changer in terms of efficiency, consistency, and overall weld quality, contributing to safer, more reliable vehicle repairs.

Advantages of Using TIG Welding Collision Systems for Cleaner and Stronger Welds

TIG welding collision systems offer a multitude of advantages when it comes to achieving cleaner and stronger welds, making them a preferred choice in various industries, including automotive. These systems employ a precise and controlled collision of arc and gas, resulting in minimal spatter and heat-affected zones. This not only ensures a neater, more aesthetically pleasing finish but also preserves the integrity of the surrounding material, crucial for auto body services and auto body painting.

Moreover, TIG welding collision systems enable greater control over weld parameters, allowing for consistent and high-quality results. This precision is particularly beneficial for intricate auto body work, where maintaining structural integrity while achieving a clean look is paramount. By minimizing distortion and maximizing strength, these systems deliver superior welds that withstand the rigors of modern transportation and industrial applications.

Application Examples: Where TIG Welding Collision Systems Shine

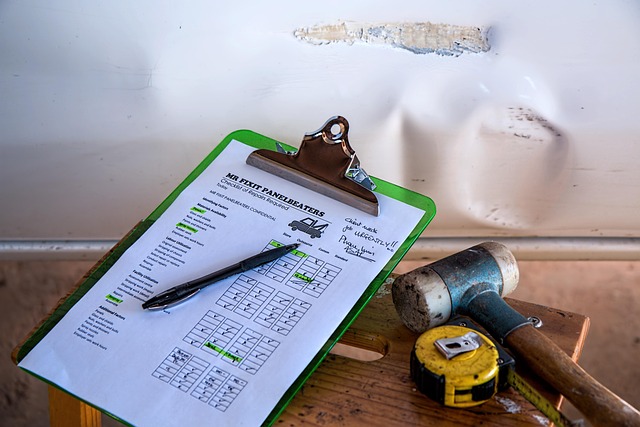

TIG welding collision systems are particularly effective in various industries where precision and strength are paramount. In vehicle collision repair, for instance, these systems ensure clean and robust welds on car bodies, facilitating faster and more efficient repairs. Auto repair shops benefit from reduced rework and higher customer satisfaction due to the system’s ability to create strong bonds while minimizing heat input, thus preserving the integrity of surrounding materials.

Similarly, in car scratch repair, TIG welding collision systems offer a delicate approach. They can precisely fill and weld over minor scratches and dents, restoring the vehicle’s original appearance without damaging the paint or finish. This level of detail work is especially valuable for maintaining the value and aesthetics of high-end vehicles, making it a preferred method in premium auto repair shops.

TIG welding collision systems represent a significant advancement in the field, offering a cleaner and stronger alternative for welders. By precisely controlling the arc and gas flow, these systems eliminate excess heat and reduce spatter, resulting in high-quality, consistent welds. As demonstrated in various industrial applications, TIG welding collision systems are a game-changer, ensuring structural integrity and aesthetic appeal across diverse materials and configurations. Adopting these systems can streamline operations, enhance product quality, and drive innovation in manufacturing sectors worldwide.