TIG welding collision systems integrate precision TIG welding with CAD and sensor technology to restore vehicles to pre-accident conditions, meeting OEM standards. Skilled welders prepare and repair damaged areas, using specific parameters for each vehicle model to ensure structural integrity and aesthetic preservation. While these systems offer advanced outcomes, they require substantial upfront investment and maintenance, posing a challenge for smaller repair services.

TIG welding collision systems are pivotal in ensuring precision and quality in modern manufacturing. This advanced technology offers a precise, automated approach to welding, critical for maintaining original equipment manufacturer (OEM) specifications. By understanding these systems and their processes, manufacturers can achieve consistent results, reduce defects, and enhance overall productivity. This article delves into the intricacies of TIG welding collision systems, exploring key processes, benefits, and challenges in implementation.

- Understanding TIG Welding Collision Systems

- Maintaining OEM Specifications: Key Processes

- Benefits and Challenges in Implementation

Understanding TIG Welding Collision Systems

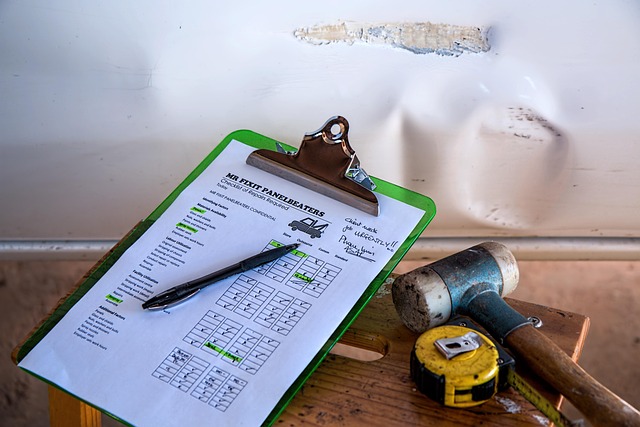

TIG welding collision systems are designed to ensure precision and accuracy during the repair process, maintaining OEM (Original Equipment Manufacturer) specifications. These systems employ a unique approach by combining TIG welding techniques with advanced collision repair methodologies. TIG welding, known for its high-quality, strong welds, is further enhanced through specialized software and hardware configurations. This enables collision repair centers, or auto collision centers, to precisely replicate the original vehicle design and structural integrity.

When it comes to fleet repair services, understanding TIG welding collision systems is paramount. By adhering to OEM specifications, these systems not only restore vehicles to their pre-accident condition but also ensure safety and reliability for commercial fleets. The meticulous process involves advanced sensor technology and computer-aided design (CAD) software to map and measure the damage accurately, allowing for precise repairs that match the quality of the original manufacturing standards.

Maintaining OEM Specifications: Key Processes

Maintaining OEM specifications is a critical aspect of TIG welding collision systems. These advanced systems are designed to ensure that every weld accurately replicates the original equipment manufacturer (OEM) standards, guaranteeing both structural integrity and aesthetic precision. The process begins with meticulous preparation, where technicians carefully inspect and clean the damaged area, ensuring it’s free from contaminants. This includes using specialized cleaning solutions and techniques to prepare the surface for welding, a step essential in achieving robust bonds.

Once ready, the TIG (Tungsten Inert Gas) welding process takes center stage. Skilled welders employ this precise method, utilizing a non-consumable tungsten electrode to create a strong, clean weld. The collision systems are programmed with specific parameters for each vehicle model and part, ensuring every weld meets OEM requirements. This level of customization not only maintains structural integrity but also preserves the original look and feel of the auto body, making it nearly indistinguishable from the rest of the vehicle—a key consideration for those seeking reliable auto repair near me or professional automotive collision repairs.

Benefits and Challenges in Implementation

Implementing TIG welding collision systems offers a myriad of benefits for both automotive restoration and vehicle repair professionals. These advanced systems ensure precision and consistency in weld quality, adhering to Original Equipment Manufacturer (OEM) specifications. By automating certain aspects of the welding process, they minimize human error, resulting in stronger and more reliable bonds. This is particularly crucial in intricate vehicle repair where maintaining structural integrity is paramount.

However, adopting these collision systems also presents challenges. They often require significant upfront investment in technology and training to ensure efficient operation and maintenance. For smaller automotive repair services, this can be a steep barrier. Additionally, keeping up with the latest software updates and calibrations is essential to maintain accuracy, demanding dedicated time and resources from skilled technicians. Nonetheless, despite these hurdles, the benefits of TIG welding collision systems make them a game-changer in modern automotive restoration and vehicle repair, ensuring high-quality outcomes that meet or exceed OEM standards.

TIG welding collision systems are invaluable tools for maintaining original equipment manufacturer (OEM) specifications. By accurately simulating weld parameters, these systems ensure consistent quality and precision, meeting the stringent standards set by automakers. While implementation involves considerations like system calibration and operator training, the benefits—including reduced rework, improved efficiency, and enhanced product consistency—outweigh the challenges, making TIG welding collision systems a game-changer in the automotive manufacturing landscape.