TIG welding collision systems revolutionize automotive repair with precise, efficient manipulation of gas and arcs for structural and aesthetic restoration. They significantly reduce repair time, enhance safety, streamline processes, ensure integrity in complex areas, offer cost-effective solutions, and provide long-lasting durability, transforming car body restoration in the digital age.

TIG welding collision systems are revolutionizing safety in post-collision scenarios, addressing critical gaps left by traditional methods. Understanding these advanced systems involves grasping their ability to detect and mitigate damage instantly. This article delves into the workings of TIG welding collision systems, highlighting how they play a pivotal role in enhancing safety immediately after collisions occur. Through exploring advanced technology, we uncover the indelible impact these systems have on minimizing injuries and property damage.

- Understanding TIG Welding Collision Systems

- Post-Collision: The Role of These Systems

- Enhancing Safety through Advanced Technology

Understanding TIG Welding Collision Systems

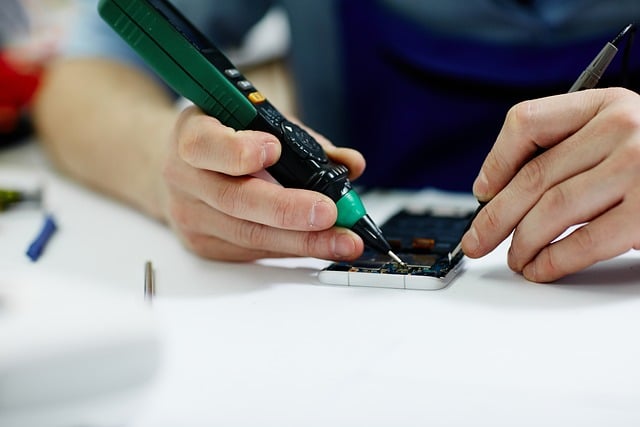

TIG welding collision systems are designed to mitigate the impact of accidents and collisions on vehicles, especially in the automotive industry. These systems go beyond traditional repair methods by focusing on both structural integrity and aesthetic restoration. When a vehicle suffers hail damage or other types of collision, these advanced systems come into play, ensuring that the repair process not only reinforces the car’s structure but also maintains its original quality and appearance.

Comprised of sophisticated technology and expertise, TIG welding allows for precise manipulation of high-intensity gas and electrical arcs to fuse metal components together. In fleet repair services or vehicle body repair scenarios, this method is invaluable. It enables technicians to accurately mend crushed panels, bent frames, and other damage, restoring the vehicle to its pre-collision state. By employing these collision systems, repair shops can offer efficient and reliable solutions for various vehicle repairs, ensuring customer satisfaction and safety on the road.

Post-Collision: The Role of These Systems

In the aftermath of a collision, traditional automotive repair methods often involve significant time and effort to address damage, including laborious car dent removal and intricate car restoration processes. However, with the advent of TIG welding collision systems, this landscape is transforming dramatically. These cutting-edge systems play a pivotal role in enhancing safety post-collision by facilitating swift and precise repairs.

By employing advanced techniques, TIG welding collision systems streamline the repair process, making it more efficient and cost-effective. Unlike manual methods, these systems minimize the risk of further damage or weaknesses in the vehicle’s structure during repair, ensuring structural integrity and safety. This is particularly crucial for complex geometric areas that were once challenging to restore using conventional methods, now offering a smoother transition towards seamless car restoration.

Enhancing Safety through Advanced Technology

In today’s digital era, advanced technologies are revolutionizing various industries, and automotive safety is no exception. TIG welding collision systems stand out as game-changers in the field of car body restoration and auto maintenance. These systems utilize cutting-edge technology to enhance the structural integrity of vehicles post-collision, ensuring safer driving conditions. By employing precise and controlled welding processes, these systems can repair and reinforce damaged areas, restoring the vehicle’s original strength and stability.

This modern approach goes beyond traditional methods, offering a more efficient and effective solution for car scratch repair and overall automotive safety. The technology behind TIG welding collision systems enables mechanicians to navigate complex repairs with ease, resulting in superior structural bonds that surpass industry standards. This advanced technology not only quickens the restoration process but also guarantees long-lasting durability, giving vehicle owners peace of mind on the road.

TIG welding collision systems play a pivotal role in enhancing safety post-collision, demonstrating that advanced technology can revolutionize industrial practices. By quickly detecting and mitigating potential risks, these systems ensure a safer working environment for welders and surrounding personnel. Through continuous innovation, TIG welding collision systems are not just responding to immediate collisions but proactively preventing future accidents, making them an indispensable component of modern manufacturing.