TIG welding, known for its precision and strength in metal joining, faces challenges in automotive repair due to intricate designs and contamination risks. The integration of TIG welding collision systems has revolutionized manufacturing across industries, offering real-time correction for optimal welds and minimizing errors. Originally popular in aerospace and automotive sectors for structural integrity and aesthetic appeal, these advanced systems are now gaining traction in mainstream applications like car body shops and tire services, ensuring precise metal fabrication with reduced waste and enhanced product quality.

In today’s advanced manufacturing landscape, TIG welding—a precise and versatile technique—is facing unique challenges. The growing demand for efficient, high-quality output has sparked the emergence of TIG welding collision detection systems. This article delves into understanding TIG welding, exploring the specific challenges it encounters, and analyzing the rapid adoption of collision systems within industries. By examining trends and benefits, we uncover how these innovative solutions are revolutionizing TIG welding processes, ensuring precision, safety, and productivity.

- Understanding TIG Welding and Its Unique Challenges

- The Emergence of Collision Detection Systems in TIG Welding

- Industry Adopting TIG Welding Collision Systems: Trends and Benefits

Understanding TIG Welding and Its Unique Challenges

TIG welding, an acronym for Metal Inert Gas welding, is a specialized technique used to join metals with precision and strength. This process involves directing a concentrated beam of heat through a non-consumable tungsten electrode, which fuses the base materials together. TIG welding is renowned for its versatility, ability to create intricate designs, and high-quality outcomes in various industries, from automotive to aerospace. However, it presents unique challenges due to its complexity.

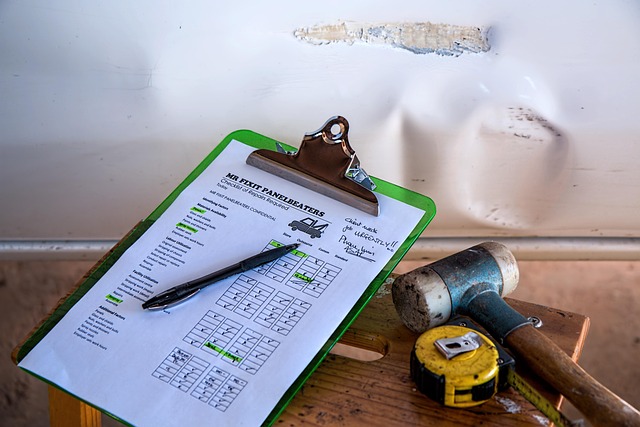

One of the primary difficulties lies in maintaining precise control during the welding process. Auto body repair and automotive repair shops often deal with delicate components and complex shapes, making accurate collision systems essential for successful TIG welding. Moreover, ensuring a clean and controlled environment is crucial to prevent contamination and achieve high-quality welds, which is particularly important when addressing car scratch repairs or intricate detail work in the automotive sector.

The Emergence of Collision Detection Systems in TIG Welding

The integration of collision detection systems into TIG welding processes has marked a significant shift in industrial practices, driven by the growing demand for efficient and precise manufacturing. Traditional welding techniques often relied on manual inspection and adjustment, leading to time-consuming errors. However, modern TIG welding collision systems employ advanced sensors and computer-aided technologies to detect even the slightest deviations from optimal welding paths. This innovation is particularly pivotal in industries such as automotive repair and paintless dent repair, where maintaining precision is not just ideal but crucial for ensuring structural integrity and aesthetic appeal.

These systems offer real-time feedback, allowing welders to make instantaneous adjustments during the process, thereby enhancing accuracy and productivity. The applications extend beyond automotive repair and body shop services; they cater to various sectors that require high-quality, consistent welding, from aerospace manufacturing to heavy machinery production. By minimizing errors and waste, TIG welding collision systems not only contribute to cost savings but also elevate the overall quality of finished products.

Industry Adopting TIG Welding Collision Systems: Trends and Benefits

The adoption of TIG welding collision systems is steadily gaining traction across various industries, driven by the remarkable benefits they offer in terms of precision and efficiency. This advanced technology, once predominantly confined to specialized sectors like aerospace and automotive manufacturing, is now making its way into mainstream applications, especially in the realm of car body shops and tire services.

The trend towards TIG welding collision systems underscores a broader shift within the auto body shop and tire service industries towards precision-welding solutions that minimize damage and waste. These systems are particularly valuable for intricate metal fabrication tasks, enabling professionals to achieve clean, seamless welds with remarkable accuracy. This is especially crucial in sectors where quality and safety are paramount, such as in auto body repair, ensuring that vehicles return to the road with structural integrity intact.

TIG welding collision systems are transforming industrial practices by addressing the unique challenges of this precise welding method. As demand grows, industries are embracing these innovative systems for their enhanced safety, efficiency, and quality outcomes. The future looks bright for TIG welding, with ongoing advancements promising to further revolutionize manufacturing processes worldwide.