TIG welding collision systems are transforming automotive repairs with their advanced blend of Tungsten Inert Gas welding techniques and sensor technology, enabling precise real-time adjustments for superior weld quality. This technology, known for its meticulous control over heat sources, minimizes distortion and damage during delicate operations like car paint and fender repair. By automating the process, these systems reduce human error, streamline services, and enhance efficiency in collision centers, making them indispensable for high-quality automotive manufacturing and repairs, including luxury brands like Mercedes Benz.

“Unleash the power of precision with TIG welding collision systems—a game-changer in the manufacturing landscape. This comprehensive guide explores the intricate world of TIG (Tungsten Inert Gas) technology and its unique advantage in collision detection. From understanding the fundamentals to uncovering real-world applications, we delve into how these systems revolutionize welding processes. Discover why TIG welding collision systems are a must-have for enhancing efficiency, accuracy, and overall productivity in today’s advanced manufacturing environment.”

- Understanding TIG Welding Collision Systems: A Comprehensive Overview

- The Unmatched Precision of TIG Technology

- Real-World Applications and Benefits: Why Collision Systems Matter

Understanding TIG Welding Collision Systems: A Comprehensive Overview

TIG welding collision systems are advanced technologies designed to enhance precision and efficiency in the field of automotive repairs. These systems utilize a unique approach by combining TIG (Tungsten Inert Gas) welding techniques with sophisticated sensor technology, enabling highly accurate alignment and repair processes. By employing these cutting-edge tools, car repair services and auto collision centers can achieve remarkable results, ensuring that vehicles return to their pre-incident condition.

In the realm of collision repair, precision is paramount. TIG welding collision systems offer a comprehensive solution by providing real-time data and feedback during the repair process. This enables skilled technicians at collision repair centers to make minute adjustments, resulting in flawless welds. With such advanced capabilities, these systems not only streamline car repair services but also elevate the overall quality of auto collision center operations.

The Unmatched Precision of TIG Technology

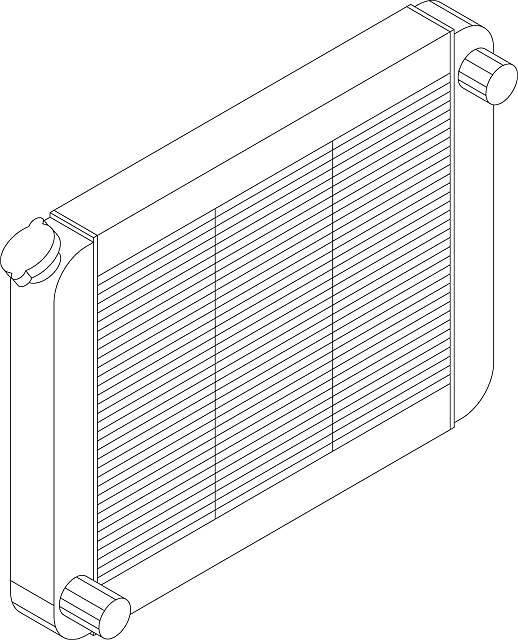

The TIG (Tungsten Inert Gas) welding process stands out for its unparalleled precision when it comes to joining metals. Unlike some welding techniques that offer a more broad, aggressive approach, TIG welding collision systems deliver a highly controlled and exacting method of fusing materials. This technology employs a non-consumable tungsten electrode that generates a focused heat source, enabling meticulous manipulation of the weld pool. The precise control over heat input and gas flow allows for minimal heat distortion, making it ideal for delicate operations like automotive repair, car paint repair, and fender repair where accuracy is paramount.

The precision advantage of TIG technology translates directly into superior results. It facilitates clean, strong welds with minimal spatter or damage to the surrounding area. This meticulousness not only ensures structural integrity but also preserves the aesthetic value of components, making it a preferred choice for high-quality craftsmanship in various industries, including automotive and body shop work where achieving flawless fender repairs is essential.

Real-World Applications and Benefits: Why Collision Systems Matter

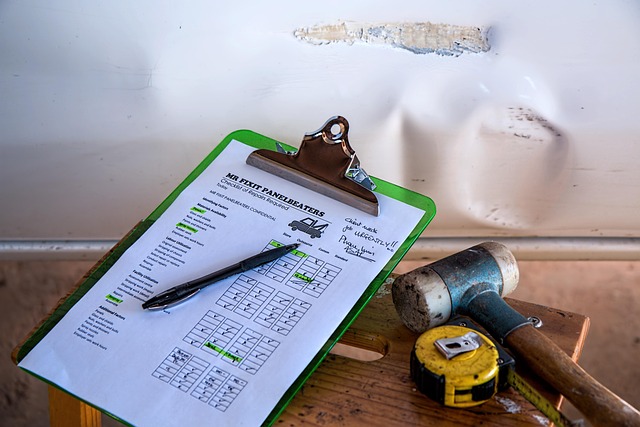

In real-world applications, TIG welding collision systems are transforming industries that rely heavily on precision and quality. From automotive manufacturing to luxury car brands like Mercedes Benz repair, these systems play a pivotal role in ensuring consistent, high-quality results. By automating the welding process, collision systems minimize human error, leading to more accurate joins and reduced waste—a significant advantage in auto maintenance and car collision repair.

This precision is particularly beneficial in complex assembly lines where even minor deviations can cause major issues. TIG welding collision systems enable technicians to focus on other critical tasks, enhancing productivity without compromising quality. Their versatility makes them indispensable tools not just for large-scale manufacturing but also for specialized workshops, ensuring that every weld meets the highest standards, be it for routine auto maintenance or extensive car collision repair work.

TIG welding collision systems offer a significant advantage in terms of precision and efficiency, making them indispensable in various industrial applications. By combining the unmatched precision of TIG technology with advanced collision detection, these systems enable more accurate and consistent welds, reducing waste and improving overall productivity. As demonstrated in real-world scenarios, the benefits of TIG welding collision systems extend beyond economic savings; they contribute to enhanced product quality and safety, solidifying their role as a game-changer in modern manufacturing.