TIG welding collision systems revolutionize auto body repairs with advanced technology, precise geometric configurations, and enhanced structural integrity. These systems streamline painting processes, maintain vehicle value retention, and are particularly effective for luxury brands like Mercedes Benz. By minimizing error margins, they enable professionals to achieve seamless welds on intricate components, ultimately reducing time and resources while maintaining top-notch quality standards in collision repair center services.

“TIG welding collision systems are transforming industrial workflows, offering unprecedented precision and control. This article delves into the intricacies of these innovative systems, providing a comprehensive overview for professionals. We explore how TIG welding collision technologies enhance accuracy, from basic principles to advanced applications. By understanding their advantages, you’ll discover why these systems are becoming the game-changer in modern welding, revolutionizing various industries and projects.”

- Understanding TIG Welding Collision Systems: A Basic Overview

- The Precision Benefits: Enhanced Accuracy and Control

- Applications and Advantages: Why TIG Welding Collision Systems Are a Game Changer

Understanding TIG Welding Collision Systems: A Basic Overview

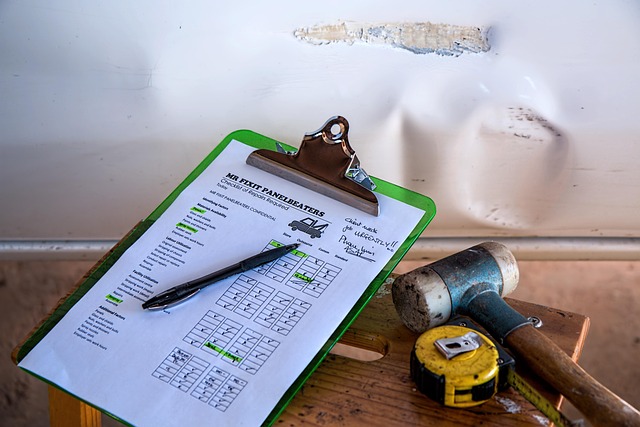

TIG welding collision systems are designed to address the intricate challenges that arise during auto body repairs, specifically focusing on precision and accuracy. These systems utilize a unique approach by combining TIG (Titanium Welding) welding techniques with advanced sensors and computer-aided control. This integration enables precise manipulation of the welding arc, ensuring consistent and high-quality welds, even in complex geometric configurations.

The primary advantage lies in their ability to handle intricate frame straightening tasks and delicate tire services without compromising on structural integrity. Moreover, these systems streamline the process of auto body painting by providing a flawless base for subsequent coating applications, thereby enhancing the overall quality and longevity of the repair work.

The Precision Benefits: Enhanced Accuracy and Control

The TIG welding collision systems offer precision advantages that significantly enhance accuracy and control during the auto collision repair or vehicle paint repair process. Unlike traditional welding methods, TIG (Titanium Gas) welding provides precise temperature control, enabling the welder to make minute adjustments with ease. This feature is particularly beneficial in complex collision repair scenarios where intricate and exact welds are required to match the original vehicle’s structure seamlessly.

With TIG welding collision systems, every aspect of the welding process can be finely tuned, resulting in stronger and more aesthetically pleasing joints. The precision benefits extend beyond just structural integrity; they also ensure that the final repair is nearly indistinguishable from the original vehicle parts, be it the body panels or intricate trim pieces. This level of control and accuracy not only improves the overall quality of collision repair center services but also maximizes the value retention of vehicles post-repair.

Applications and Advantages: Why TIG Welding Collision Systems Are a Game Changer

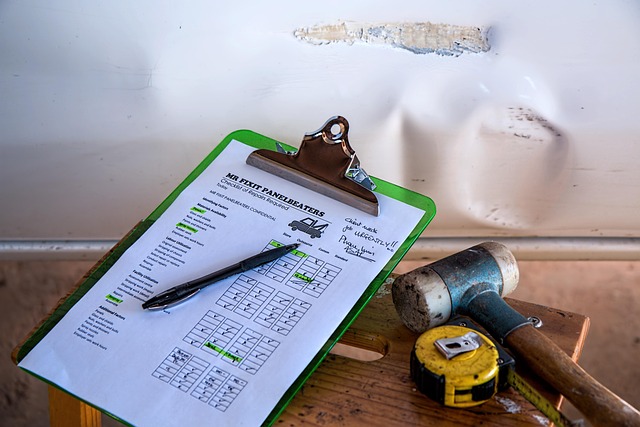

TIG welding collision systems have transformed various industries, offering unparalleled precision and efficiency. These systems are a game-changer in fields like automotive repairs, especially for luxury car brands such as Mercedes Benz repair services. The advanced technology ensures minimal error margins, making it ideal for intricate auto maintenance tasks.

By employing TIG welding collision systems, professionals can achieve seamless welds on complex components, enhancing the structural integrity of vehicles. This precision is particularly valuable in fine-tuning and repairing high-end automobiles, where every detail matters. It streamlines the process, reducing the time and resources required for car repair services while maintaining top-notch quality standards.

TIG welding collision systems offer a remarkable advantage in precision, revolutionizing the way we approach metal fabrication. By enhancing accuracy and control, these systems are a game-changer for various industries, ensuring superior quality and efficiency. The unique benefits of TIG welding collision technology, as highlighted in this article, make it an essential consideration for modern metalworking practices.